Water pumps are used to provide a continuous supply of water and to transport various forms of liquid. Firstank’s water pumps are divided into three categories based on their use: domestic, civilian, and industrial. A domestic pump is usually installed inside the house or in the courtyard with a shelter for daily domestic use. Civilian and industrial pumps are commonly installed in multi-story buildings, worksites, stores, workshops, and farms.

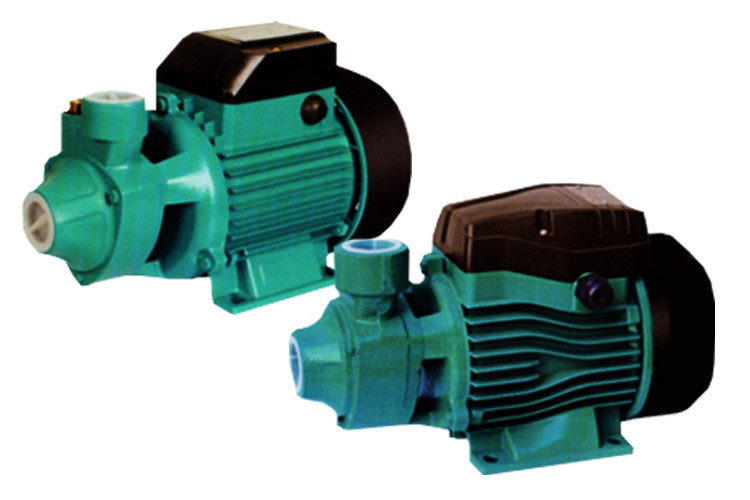

We design different pumps for various kinds of fluids, such as clean water, dirty water, water with fine sand, hot water, diesel oil, and hot oil. You may choose from the three types of pumps that we offer: peripheral pump, centrifugal pump, and jet pump. All of our water pumps are highly reliable, economical, and simple to use.

How to choose a pump?

Note: This guide is intended for general users to choose our products. Regularly, advice from your design office or pump installation departments should be your primary consideration.

Before purchasing a pump, please consider the following points in advance. This will enable you to understand more about water pumps and choose the most suitable one for your needs.

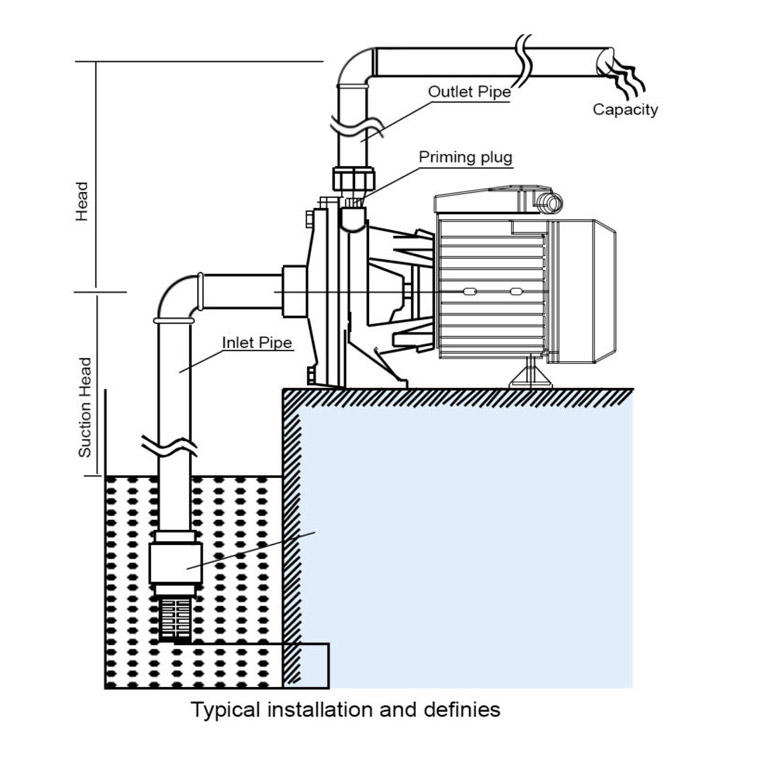

How many capacity and head do you need?

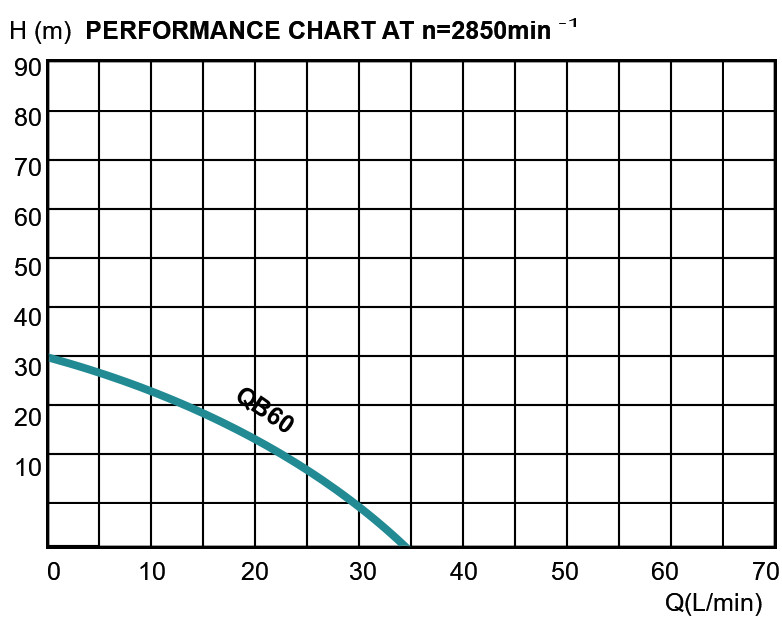

According to the practical capacity and head required, select the type of pump from the performance chart provided. It is best to place the pump’s optimal operating point within the running range of the pump. The optimal operating point of a pump is usually its rated point.

However, there may be several types of pumps that satisfy both your capacity and head requirements. In that case, please refer to other points on this site before making a final decision.

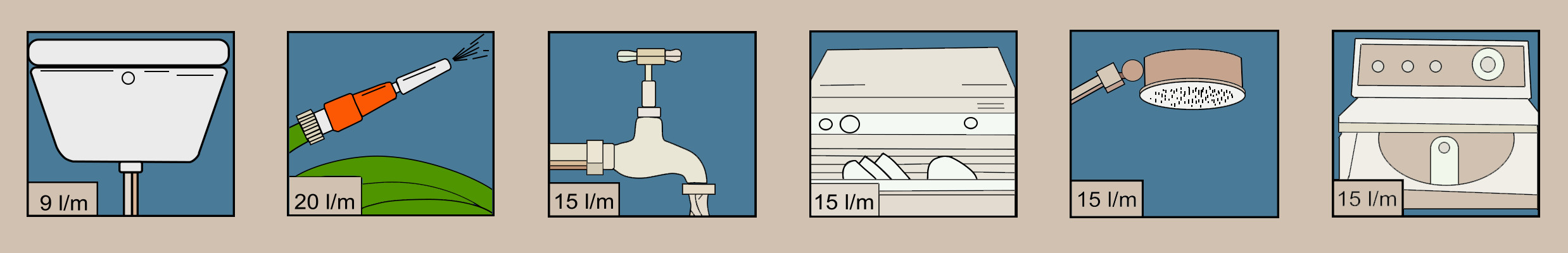

An example-hose may liters a minute do you need in your house.

The amount of water that some common home appliances typically use is indicated in the adjacent sketches. Please refer to the operating performance table to select the Elestar model that suits your needs.

For example, on the second floor, about 3 meters above your pump, suppose the most appliances likely to be operating at once are a tap (15L/min) and a washing machine (15L/min), giving a total of 45L/min. Then, check for a pump with a flow rate of 45L/min at a head of 3-5 meters, such as the J100S.

In what particular field your pump is used for?

Pumps for different use, they cost different materials and the price may be quite different, thought the performance and appearance of them are the same. We divided our pumps into three kinds use: domestic, civilian and industrial. Domestic pump is usually installed inside the house or in the courtyard with a shelter for domestic daily use. Usually the convey clean liquids and non-aggressive chemical fluids. And the pumps for civil use are installed in storied building, work-site, store, workshop, country or farm for distributing water irrigation, cooling, fireproofing, etc.

Usually, pumps design only for domestic use, it would not be used for civilian and industrial use otherwise, it will may be worn out quickly or even be damaged some time. In the other hand, it is unnecessary to use a civilian or industrial pump for a domestic occasion.

What kind of fluid be transmitted?

We design different pumps for different fluid: clean water, dirty water, water with fine sand, hot water, diesel oil or hot oil. Make sure that your pump would be suitable for the transmitted fluid. Avoid using the clean water pump to deliver sewage because it will cause of blocked impeller and burning down the electric motor. Do not use a dirty water pump to deliver clean water prevent the decline of its efficiency and waste energy. Ordinarily, the ambient temperature should not over 40 C and the fluid temperature should not exceed over Max temperature. If you need pumps for higher temperature fluid. Please advise us. We will find a solution for you.

What kind of pump would you choose?

We have three kinds of pumps for you to select from: peripheral pump, centrifugal pump, and jet pump. Suppose all types of pumps operate at the same power. In that case, the peripheral pump provides a higher head but lower capacity compared to the centrifugal and jet pumps. It can achieve a higher head in an economical way. Centrifugal pumps offer larger capacity and higher efficiency than peripheral and jet pumps. They are a good choice for applications with large power consumption to save energy. The jet pump provides a more reliable output.

About the suction head

Due to atmospheric pressure, there is a certain suction head for a given fluid. For example, for water, the maximum suction lift of an ordinary domestic pump is about 8 meters. Even if the suction pipe were pumped to a vacuum, the maximum suction head would only be about 10 meters. However, choose a deep well pump instead when a deeper suction, such as 15 meters, is required. A deep well pump consists of two parts: a jet pump and a centrifugal pump. Pay attention to the NPSH (net positive suction head) when using industrial or civilian pumps to ensure stable and continuous operation. For domestic pumps, NPSH is usually not taken into consideration.

Advise

It is preferable to consider a pump driven by an electric motor. Usually, some pumps cannot be operated across their entire head range. Avoid operating a centrifugal pump under conditions of low head outside its range, as this will overload the pump—the lower the head, the more power is required. Conversely, never operate a peripheral pump under conditions of high head outside its range, as this will also overload the pump—the higher the head, the more power is required. Therefore, ensure the pump operates within its designated range. For a jet pump, its power changes little with variations in head or capacity, making it suitable for use across its entire head range.

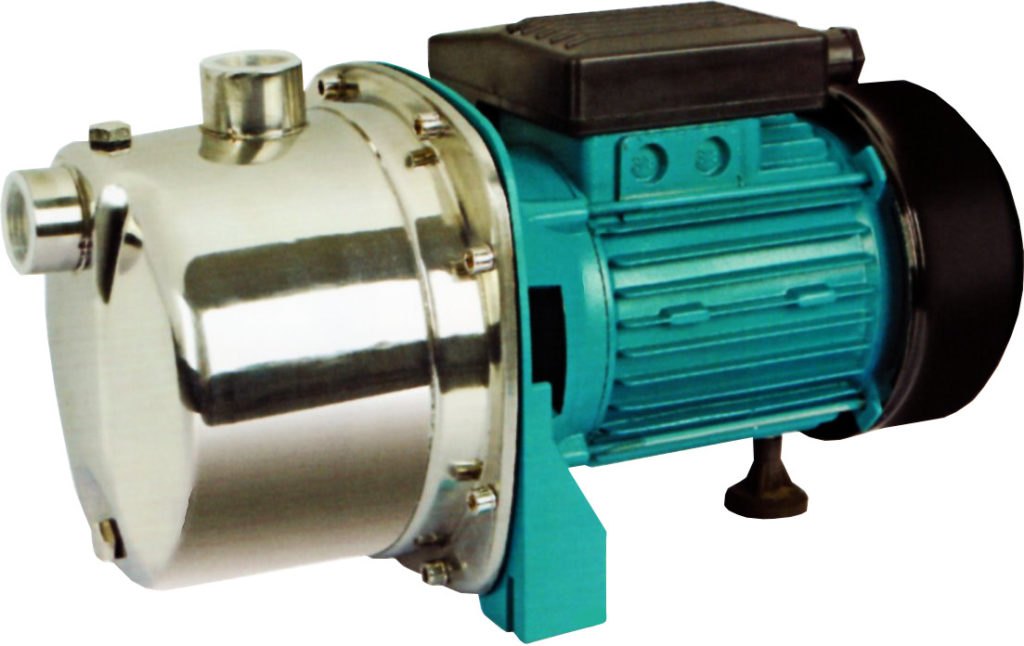

These pumps are suitable for handling clean water not containing abrasive particles and fluids which are not chemically aggressive to the pumps components. Reliable, economical and simple to use, they are suitable for domestic applications and the automatic distribution of water from surge tanks, watering gardens and for boosting insufficient mains water pressure. These pumps should be installed in a covered area, protected against the weather.

PERFORMANCE RANGE

- Flow rate up to 36 L/min. (2.1 m^3/h)

- HEAD up to 36m

STANDARD DATA AND EQUIPMENT

Single phase 220V/50Hz. Brass impeller, carbon steel motor shaft, with thermal protector inside. Other model and material such as three phase, 110V, 60Hz, dual voltage, stainless shaft, etc, will be available upon request.

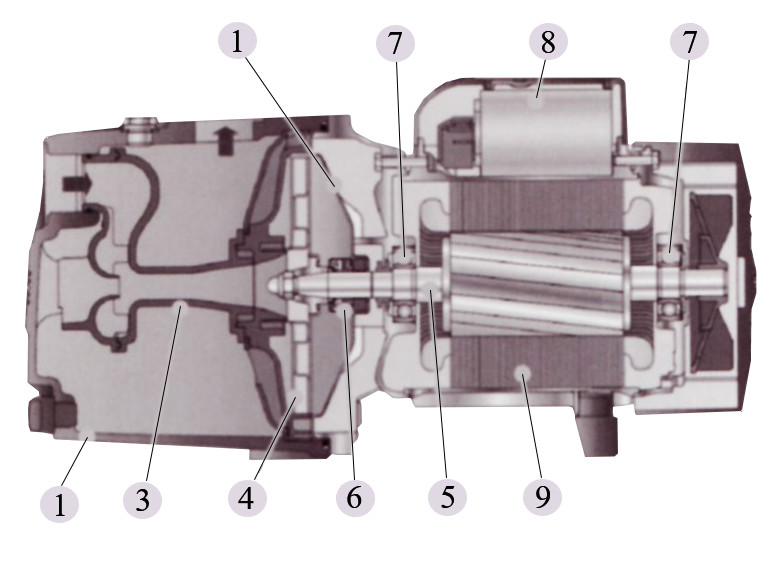

| POS. COMPONENT | CONSTRUCTION CHARACTERISTICS | |||||

|---|---|---|---|---|---|---|

| 1. PUMP BODY | Cast iron, complete with threaded ports in compliance with ISO228/1 | |||||

| 2 MOTOR BRACKET | Aluminum | |||||

| 3. IMPELLER | Brass, with peripheral radial vanes | |||||

| 4. MOTOR SHAFT | Stainless steel EN 10088-31.4104 | |||||

| 5. MECHANICAL SEAL | Pump | Seal | Shaft | Materials | ||

| Model | Model | Diameter | Stationary ring | Rotational ring | Elastomer | |

| QB60 | AR-12 | 12mm | Ceramic | Graphite | NBR | |

| 6. BEARING | Pump | Model | ||||

| QB60 | 6201 ZZ / 6201 ZZ | |||||

| 7. CAPACITOR | Pump | Capacitance | ||||

| Single-phase | (230V or 240V) | |||||

| QB60 | 10 uF 450VL | |||||

| 8. ELECTRIC MOTOR | QB: single-phase 230V – 50Hz with thermal overload protector built-in to the winding. | |||||

| QB: three-phase 230/400V – 50Hz | ||||||

| Pumps fitted with the three-phase motor option offer IE2 (IEC60034-30) class high performance | ||||||

| -Insulation:F class. | ||||||

| -Protection:IP 44. | ||||||

OPERATING LIMITS

- Suction lift up to 9 m

- Fluid temperature up to 60 C

- Maximum ambient temperature 40 C

TECHNICAL DATA

| TYPE | POWER KW HP | H MAX m | Q MAX L/min | SIZE Inch | S HEAD m | PACKING QTY |

|---|---|---|---|---|---|---|

| QB 60 | 0.37 0.50 | 36 | 36 | 1″ x 1″ | 9 | 3720 |

These pumps are suitable for pumping clean water and fluids which are not chemically aggressive to the pump components. They are extremely reliable, economical and simple to use, being particularly suitable for domestic applications such as the automatic distribution of water from small and medium-sized surge tanks, watering gardens, etc. These pumps should be installed in a covered area, protected against the weather. N.B. it is always advisable to install a foot valve or non-return valve or non-return valve on the suction opening.

PERFORMANCE RANGE

- Flow rate up to 60 L/min. (3.6 m^3/h)

- HEAD up to 45m

STANDARD DATA AND EQUIPMENT

Single phase 220V/50Hz. Brass impeller, carbon steel motor shaft, with thermal protector inside. Other model and material such as three phase, 110V, 60Hz, dual voltage, stainless shaft, etc, will be available upon request.

| POS. COMPONENT | CONSTRUCTION CHARACTERISTICS | |||||

|---|---|---|---|---|---|---|

| 1 PUMP BODY | Stainless steel, complete with threaded ports in compliance with ISO228/1 | |||||

| 2 BODY BACKPLATE | Stainless steel AISI 304 | |||||

| 3 NOZZLE ASSEMBLY | Noryl FE1520PW | |||||

| 4 IMPELLER | Stainless steel AISI 304 | |||||

| 5 MOTOR SHAFT | Stainless steel AISI 304 EN 10088-31.4104 | |||||

| 6 MECHANICAL SEAL | Pump | Seal | Shaft | Materials | ||

| Model | Model | Diameter | Stationary ring | Rotational ring | Elastomer | |

| J100S | AR-14 | 14 mm | Ceramic | Graphite | NBR | |

| 7 BEARINGS | 6203 ZZ/6203 ZZ | |||||

| 8 CAPACITOR | Pump | Capacitance | ||||

| Single-phase | (230 V or 240 V) | (230 V or 240 V) | ||||

| J100S | 20 uF 450 VL | 40 uF 300 VL | ||||

| 9 ELECTRIC MOTOR | JS: single-phase 230V – 50Hz with thermal overload protector built-in to the winding. | |||||

| JS: three-phase 230V – 50Hz | ||||||

| Pumps fitted with the three-phase motor option offer IE2 (IEC60034-30) class high performance | ||||||

| Stator and rotor are made out of magnetic sheet with low iron loss. | ||||||

| -Insulation:F class. | ||||||

| -Protection:IP 44. | ||||||

OPERATING LIMITS

- Suction lift up to 9 m

- Fluid temperature up to 60 C

- Maximum ambient temperature 40 C

TECHNICAL DATA

| TYPE | POWER KW HP | H MAX m | Q MAX L/min | SIZE Inch | S HEAD m | PACKING QTY |

|---|---|---|---|---|---|---|

| J100S | 0.75 1.0 | 45 | 60 | 1″ x 1″ | 8 | 1600 |

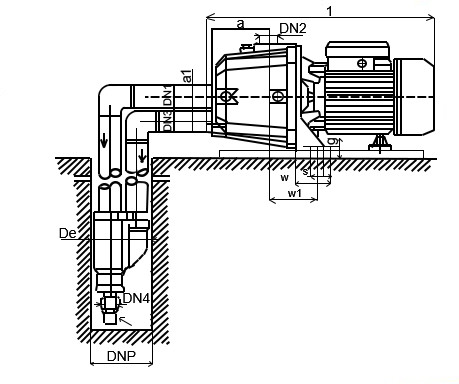

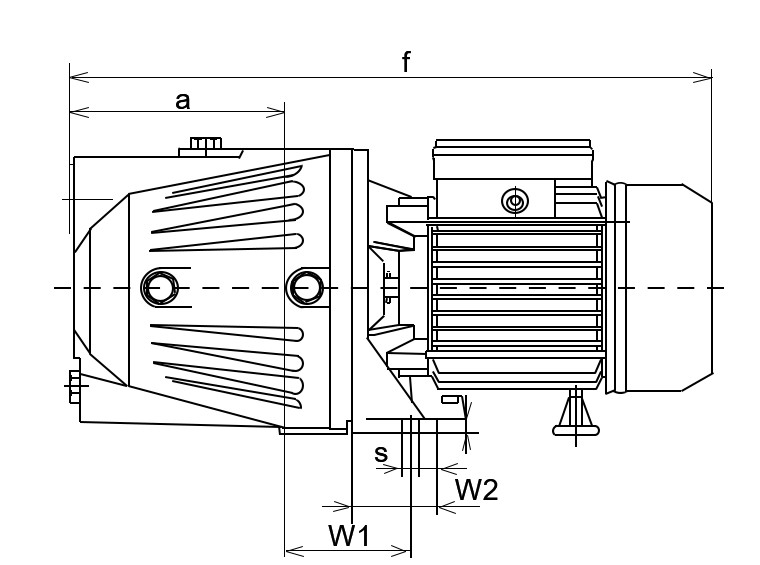

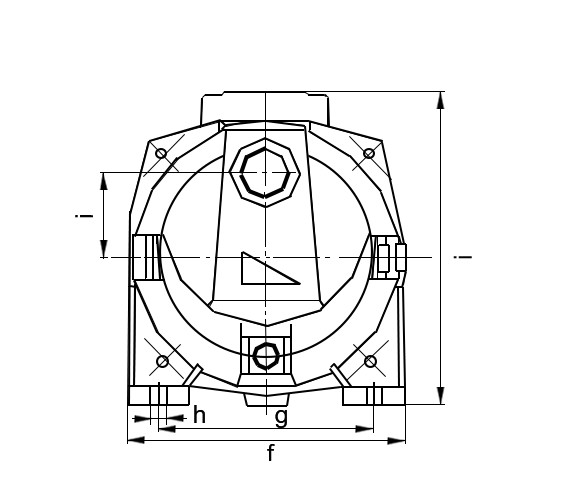

DP 370 are self-priming deep well pumps suitable for pumping clean water. They are particularly suitable for domestic applications such as pumping water from deep well, pool, the automatic distribution of water by surge tanks and pressure switch, gardening, and increasing water pressure.

WORKING CONDITIONS

- Max Temperature of Fluid up to +50 C

- Max Pressure up to 10 bar

- Max Ambient temperature up to 40 C

TECHNICAL DATA

| Input Power | Current | Capacitor | Size | Total Head | Injector Type | Sect. H | Capacity l/min At discharge head m | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.37 | 0.5 | 2.4 | 16 | 1.25″ x 1″ x 1″ | 50 | E20 | 10 | 42 | 18 | 15 |

| E20 | 15 | 25 | 16 | 10 | ||||||

| E30 | 20 | 20 | 10 | 7 | ||||||

JET-B Series cast iron self-priming pumps are mainly used to transfer clean water and other liquid which is similar with water character. It is suitable for industrial and urban water supply, pressure rise for high building, garden irrigating, long distance water transfer and relevant equipment etc.

OPERATING CONDITIONS

- Liquid temperature up to 60 C

- Ambient temperature up to 40 C

- Total suction lift up to 9 m

- Continuous duty

CONSTRUCT

- Single Phase

- Heavy Duty Continuous Work

- Motor Housing: Aluminum Alloy

- Shaft: Carbon steel / Stainless Steel

- Insulation: Class B / Class F

- Protection: IP 44 / IP 54

- Cooling: External Ventilation

- Pump Body: Cast Iron

- Impeller: Brass / Techno-polymer (P.P.O) / Stainless Steel

- Mechanical Seal: SIC / Ceramic / Graphite

TECHNICAL DATA

| Model | Output Power | Q.max (L/min) | H.max (m) | S.Head (m) | Speed (r/min) | Capacity (l/min) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | HP | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||||||

| JET-60B | 0.37 | 0.5 | 42 | 40 | 9 | 2850 | Total head(m) | 40 | 32 | 30 | 27 | 25 | 23 | 20.5 | 17 | 4 | – | – |

| JET-80B | 0.55 | 0.75 | 48 | 48 | 9 | 2850 | 48 | 38 | 35 | 33 | 30 | 28 | 26 | 24 | 19 | 5 | – | |

| JET-100B | 0.75 | 1 | 54 | 52 | 9 | 2850 | 52 | 42 | 39 | 37 | 35 | 32 | 30 | 28 | 26 | 16 | 5 | |

| JET-120B | 1.1 | 1.5 | 55 | 60 | 9 | 2850 | 60 | 56 | 53 | 49 | 46 | 43 | 40 | 38 | 33 | 25 | 12 | |

| JET-140B | 1.5 | 2 | 60 | 70 | 9 | 2850 | 70 | 65 | 61 | 57 | 54 | 50 | 47 | 43 | 38 | 33 | 22 | |

JSW 15M are cast iron self-priming pumps are mainly used to transfer clean water and other liquid which is similar with water character. It is suitable for industrial and urban water supply, pressure rise for high building, garden irrigating, long distance water transfer and relevant equipment etc.

OPERATING CONDITIONS

- Liquid temperature up to 60 C

- Ambient temperature up to 40 C

- Total suction lift up to 9 m

- Continuous duty

CONSTRUCT

- Single Phase

- Heavy Duty Continuous Work

- Motor Housing: Aluminum Alloy

- Shaft: Carbon steel / Stainless Steel

- Insulation: Class B / Class F

- Protection: IP44/IP54

- Cooling: External Ventilation

- Pump Body: Cast Iron

- Impeller: Brass / Techno-polymer (P.P.O) / Stainless Steel

- Mechanical Seal: SIC / Ceramic / Graphite

TECHNICAL DATA (220 ~ 240V/50Hz)

| Model | Output Power | Q.max (L/min) | H.max (m) | S.Head (m) | Speed (r/min) | Capacity (l/min) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | HP | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 40 | 45 | 50 | 65 | ||||||

| JSW 15M | 1.1 | 1.5 | 60 | 70 | 9 | 2850 | Total head(m) | 70 | 67 | 64 | 61 | 57 | 54 | 50 | 47 | 44 | 40 | 35 |